Steaming Resistance

Steaming Resistance

- Enables Aseptic and Retort Packaging

Withstands high-temperature steam sterilization, a mandatory process for shelf-stable food, beverage, and pharmaceutical packaging (e.g., pouches, liquid cartons, ready-to-eat meals). This ensures product safety and extends shelf life without packaging failure.

- Maintains Integrity Under Extreme Conditions

Prevents ink from blistering, discoloring, or losing adhesion to the substrate (e.g., aluminum foil, treated films) when exposed to pressurized steam, humidity, and high heat simultaneously.

- Ensures Safety and Prevents Migration

Acts as a stable barrier, preventing ink components from migrating into the food content during and after the aggressive steaming process. This is a fundamental requirement for compliance with global food contact regulations (e.g., EU 10/2011, FDA).

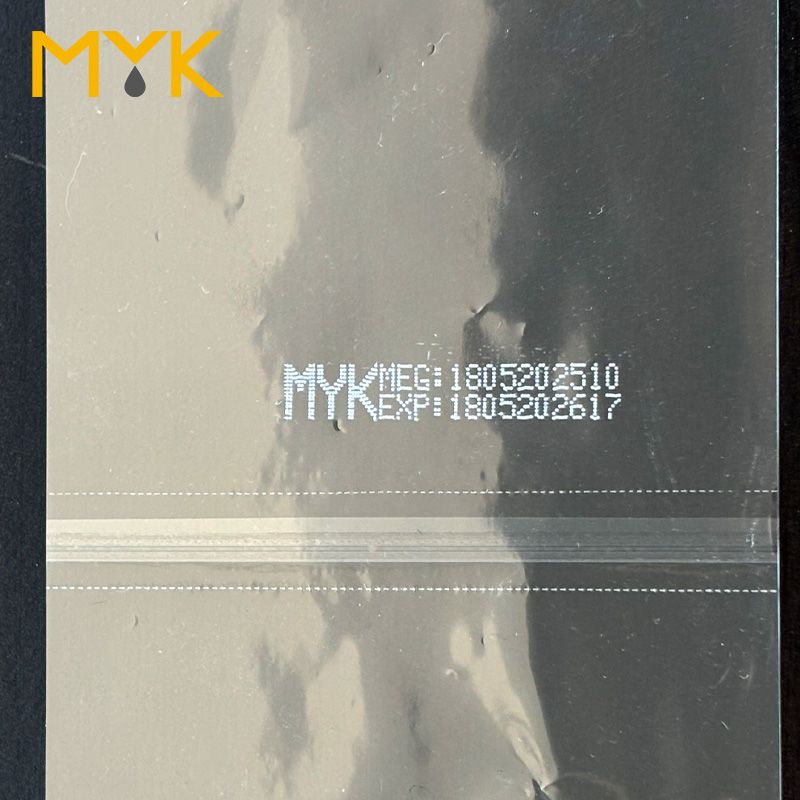

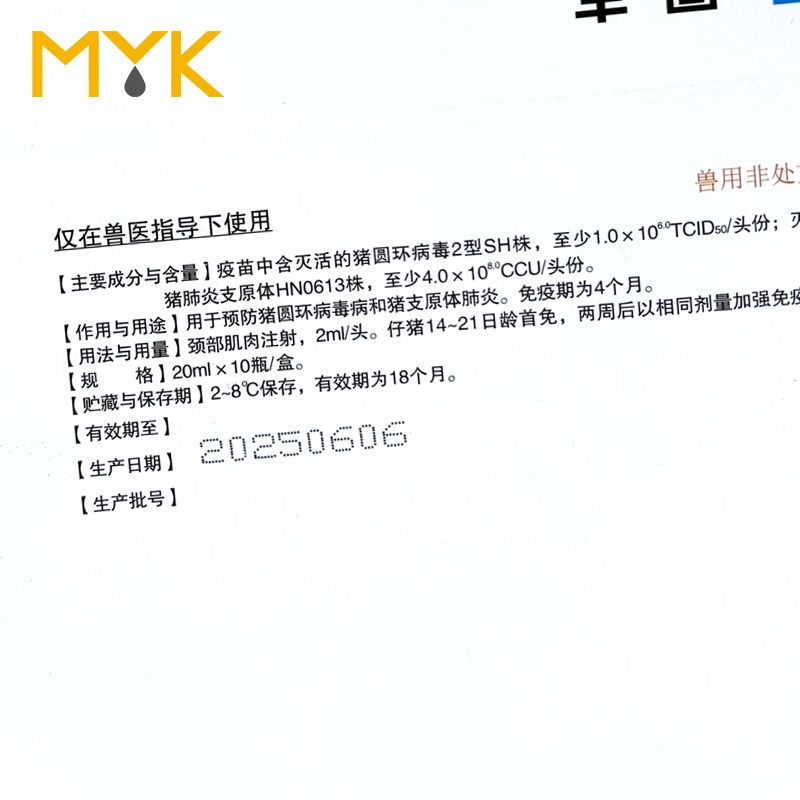

- Guarantees Legibility and Brand Presentation

Ensures all printed graphics, barcodes, and expiration dates remain sharp, smudge-free, and professionally presented after processing, which is critical for consumer trust and supply chain efficiency.